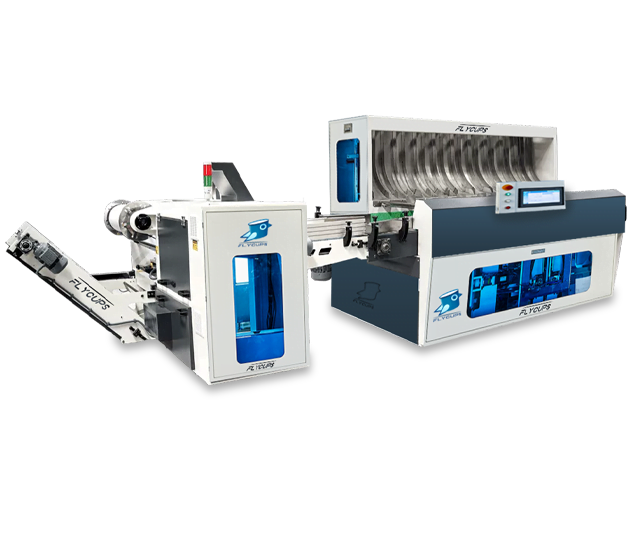

Paper Cups Counting and Packaging Machine 3 Gates Super Accuracy

Paper Cups Counting and Packaging Machine 3 Gates Super Accuracy

FLYCUPS

Paper Cups Counting and Packaging Machine 3 Gates Super Accuracy

SKU:FCPKG-3

Paper Cups Counting and Packaging Machine from FLYCUPS. The Machine is equipped with 3 Gates for cups Coming from Paper Cup Making Machines. It saves effort and time and enables you to manage your Factory more efficiently.

Share This Product :

Twitter

WhatsApp

Facebook

Cup Size Range

3-16 Oz

Capacity

9 Pack/min

Control System

PLC

Technical Specifications

| FlyCups SKU | FCPKG-3 |

| Name | Paper Cups Counting and Packaging Machine 3 Gates |

| Capacity | 9 Pakage/Min |

| Sealing Type | RESISTANCE |

| Cup Size Range | 3-16 Oz |

| Power | 5 kw |

| Control System | PLC |

| Air Consumption | 6 Bar |

| Cups in Package | 20 ~ 150 (Easily Changable) |

| Weight | 175 kg |

| Dimensions | 800-250-125 cm (L-W-H) |

| Short Description | Paper Cups Counting and Packing Machine from FLYCUPS. The Machine is equipped with 3 Gates for cups Coming from Paper Cup Making Machines. It saves effort and time and enables you to manage your Factory more efficiently. |

Why should you buy a paper cup machine from FLYCUPS?

We understand all your problems with other machines due to the long experience of our engineers. Using artificial intelligence techniques, we reach with you the highest profitability. Your customers will be satisfied with our Defect Detection Systems. Avoid wastage thanks to automatic machine stop system. Work without stop thanks to the weekly and monthly FLYCUPS Periodic Remote Performance Monitoring System.

What are the advantages of the paper cup production project?

The budget for the paper cup production project is relatively acceptable. The paper cup production project is on of the best small businesses that make profits in 2022. The sizes and graphics drawn on the paper cups vary according to the country and region in which its manufactured, and this gives flexibility in marketing to customers in your region according to the sizes and special drawings they request.

What are the stages of producing paper cups?

– In the beginning, the huge paper rolls are printed and cut into pieces (Fan Shape) according to the size. If the required cup forming machines are more than 5 machines, or you plan to expand, then we recommend purchasing a printing and cutting machine for your factory. If the cup forming machines are few, you can save money by buying printed and cutted paper from your local market. These cutted and printed papers are transferred to the cup forming machines. If the machine speed is standard or medium, we recommend that the machine be supplied manually, and to be automatic in case the machine with high speed. In cup forming machines, the cup takes its shape, the base is added to it, and it is transported through an air vacuum system to the counting table. – The cups are counted and sorted in packages with count you select, then the packaging stage are done manually on the assembly table of each machine or automatically if you have multiple cups forming machines.

What is the required space for the paper cup machine?

The paper cup machine takes an average of 8 square meters, but you need additional space to store paper and ready-made cups. We recommend that the working and warehouse space should be at least 70 square meters.

What is the difference between the production of paper cups and plastic cups and which is better?

Paper materials are easier to print than plastic. Paper cups are healthy and do not contain carcinogens or harmful to human health, unlike plastic cup machines. The budget of the paper cup making machine is relatively reasonable while the plastic cup machines require a large capital.

How much electricity does the paper cup machine consume?

FLYCUPS paper cup machines consume approximately 4 to 6 kilowatts of electrical energy.

Is the paper cups project profitable financially?

The paper cups project is one of the best small projects that make profits according to the statistics of 2022. You need to determine the most popular cup sizes and choose a good quality machine to produce the estimated number that your market needs. Purchasing the machine is the first and most important step in your project. Therefore, you should choose an acceptable quality machine with a real warranty and technical support in order to avoid a real loss in the case of the machine breaks down for a long time.

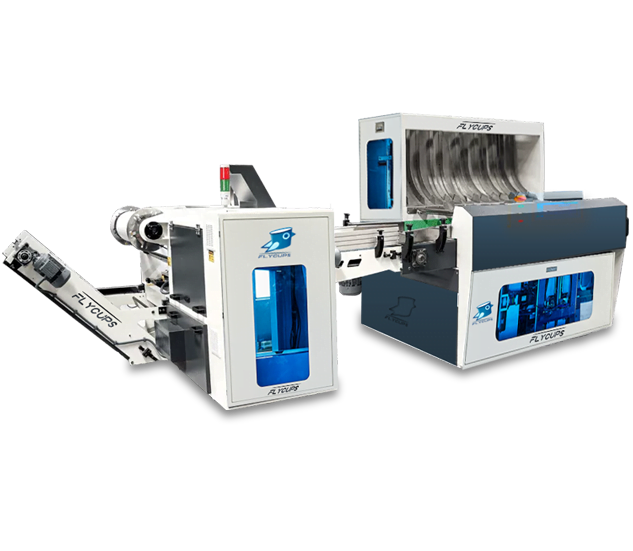

Photo Gallery :

Paper Cups Counting and Packaging Machine

Control System:

Paper Cups Counting and Packaging Machine has PLC control with error detection and optical sensor. The Touch Screen let you control all the production process from one Graphical interface.

Material:

The material of cup mold is reinforced iron instead of normal steel; thus, it’s enabling the machine to work long time without the need to re calibration of the moving parts like the legacy paper cup machine.

Transfer Cups without Stacking:

The machine has a built-in blowing air system that uses a piece of Anti-Stack Pipe for transferring paper cups safely and efficiently. The machine is also fully automatic, with an auto-counting and auto-stacking system.

For More Information