Paper Cup Making Machine Big Cups Size Medium Speed Korean Design 80 Cup per Min Very Stable

Paper Cup Making Machine Big Cups Size Medium Speed Korean Design 80 Cup per Min Very Stable

FLYCUPS

SKU:FCC-80

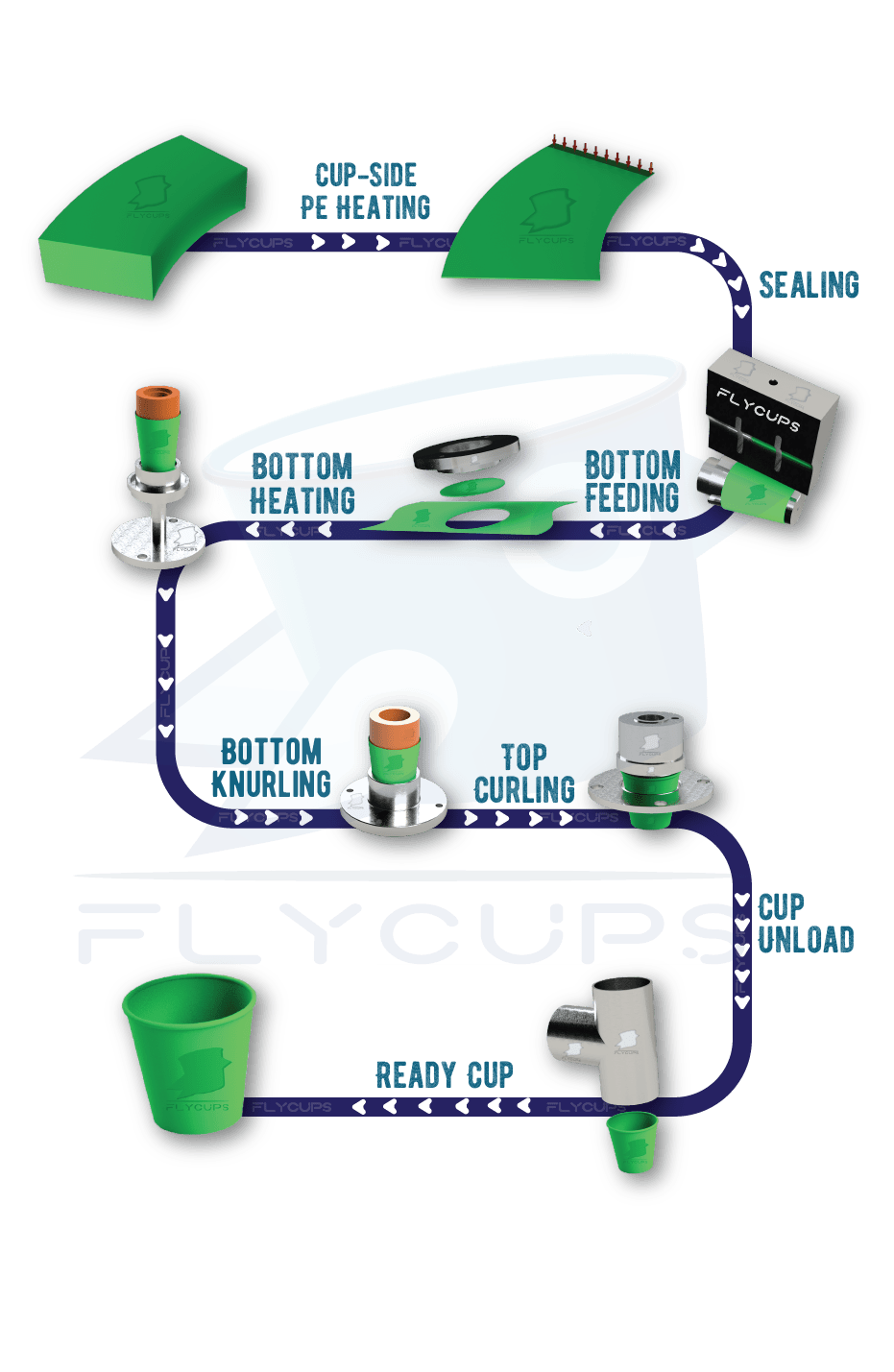

Paper Cup Making Machine With Very Stable Parts from FLYCUPS. The Machine is Equipped with SERVO and CAM System and Superior Automation System that Makes Movements more Efficient. The FLYCUPS Machine is fully Automatic and Equipped with Fault Detection Systems thanks to Sensors at all Stages of Paper Cup Manufacturing Process, so that waste is minimized.

Share This Product :

Edge Sealing

Ultrasonic & Leister

Max.Capacity

80 CUP/MIN

Electronic Control

PLC Controller

Technical Specifications

| FlyCups SKU | FCC-80 |

| Name | Paper Cup Making Machine Big Cups Size Medium Speed Korean Design 80 Cup per Min Very Stable |

| Max. Capacity | 80 Cup/Min |

| Standart Working Speed | 70 Cup/Min |

| Pre-Heating | Leister hot air system |

| Automatic Feeding System | No |

| Required Paper | 160-220 gsm single side PE coated paper |

| Cups Size | 10 OZ - 16 OZ *It should be specified at the time of the order. |

| Edge Sealing | Stage 1: Leister hot air system Stage 2: Ultrasonic bonding |

| Base Bonding | Leister hot air system in two stages |

| Paper Cup Rimming | Paper Cup Rimming has Rimming stages |

| Machine Control | Micro Computer and Touch Screen |

| Electronic Control | PLC Controller |

| Base Paper Feeding | Servo System |

| Power | 380V 50HZ 10KW |

| Air Supply Requirement | 0,4 cbm/min |

| Lubrication | Automatic |

| Working System of the Machine | Cam System and Servo Control are used in the machine and all movements are made more efficient. Thanks to the superior automation system in the machine, the waste rate has been reduced to a minimum |

| Transfer System | Automatic Counting and Transfer |

| Machine Weight | 3500 kg |

| Machine Size | 230 cm x 120 cm x 180 cm |

| Error Detection System | Optical Sensors |

| Fault Detection | Camera System (Optional) |

| Standards | CE standard |

P

r

o

d

u

c

t

i

o

n

s

P

r

o

d

u

c

t

i

o

n

s

Steps

Photo Gallery :

Paper Cup Making Machine

Sealing:

Paper Cup Making Machine is equipped with an ultrasonic sealing system, allowing it to produce cups for hot and cold beverages using single- or double-sided PE coated paper.

Lubrication System:

The machine also has an automatic lubrication system, ensuring that all mechanical parts are properly lubricated.

Cups with No Leakage:

The bottom of the paper cups are made with lower mold clamping to prevent leakage.

Control System:

The machine has PLC control with error detection and optical sensor. The Touch Screen let you control all the production process from one Graphical interface.

Material:

The material of cup mold is reinforced iron instead of normal steel; thus, it’s enabling the machine to work long time without the need to re calibration of the moving parts like the legacy paper cup machine.

Transfer Cups without Stacking:

The machine has a built-in blowing air system that uses a piece of Anti-Stack Pipe for transferring paper cups safely and efficiently. The machine is also fully automatic, with an auto-counting and auto-stacking system.

Changing Mold became Easier:

Additionally, changing molds is easier due to the well-designed parts of the machine that can be easily exchanged.

For More Information